MIND YOUR LINES

Using the right line for a particular job and preventing wear and tear are keys to smooth sailing.

By Lauren Smith

IIF YOU’RE A SAILOR, perhaps you know that moment: You’re adjusting the sails, and something doesn’t feel quite right. The line isn’t running as smoothly as it used to, or maybe there’s a concerning fuzzy spot where there shouldn’t be one. If you’re nodding your head right now, it’s time to learn what’s really happening with all those ropes you have on board.

Before we dive into the nitty-gritty, let’s clear up some terminology. That rope you bought at the marine store? Once it’s on your boat and put into use, it becomes “line.” It’s more than just sailor-speak, it’s about understanding that each piece of running rigging has its own crucial role, and using the right type of line for a particular application can affect both performance and safety.

Modern line used for running rigging consists of two components: an outer cover that is typically braided polyester, and a core that can be braided using polyester or high molecular polyester (HMPE) fibers. The cover protects the braided polyester or braided HMPE core of the line and tends to make it easier to handle. Noting the construction of the rope when purchasing it ensures you are getting the correct rope for the job it will perform.

A loose polyester line and braided cover will splice easily and offers good UV protection, but it may stretch some. That’s acceptable for smaller boats and cruising applications, and for older wooden boats, where some “give” reduces loads.

Lines for racing boats, including dinghies and sport boats, and for larger cruising boats need to be stronger, and stretch is less desirable. In these applications, a core made of HMPE fiber is preferred.

Recently we have seen fibers such as Technora and Cordura introduced into the braiding of control lines. These polyester fibers act as reinforcement to prevent abrasion. They provide core protection in high usage areas on the boat.

Another popular fiber used in marine applications is nylon. Nylon fibers are a bit weaker than their polyester counterparts. However, nylon has elasticity that can dampen the loads put on an anchor rode, mooring painter, or dockline. One consideration when sizing nylon line is the fact that when the fibers get wet, they will lose 10 to 15 percent of their strength, which means you may be replacing your nylon ropes more quickly.

Halyards do heavy lifting on a sailboat. The size of a boat will determine the type of line you will need. On boats under 35 feet, a polyester cover and core will have you cruising with ease. A larger vessel needs the strength of a line with a HMPE core to carry loads, especially in offshore conditions.

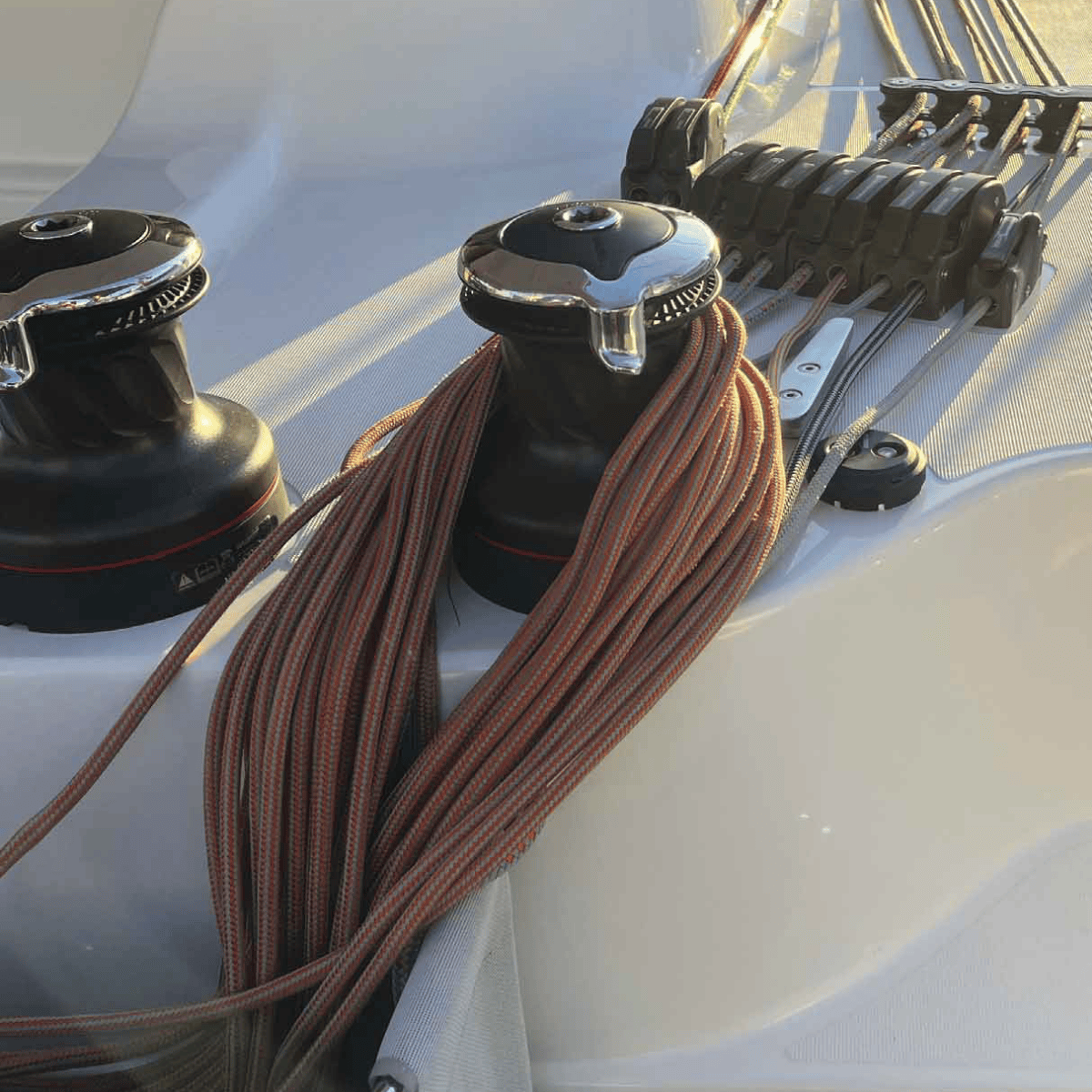

Control lines such as sheets take a beating on the deck of a vessel. Again, the size of the boat determines the type of line necessary

for smooth sailing. Under 35 feet a boat can easily carry sheets with a polyester cover and core. On bigger sailboats, we recommend a line with an HMPE core. Technora and Cordura fibers in a line are great protectors of the core where it runs through fairleads, block, and clutches. We do recommend lines with these fibers. They may be more expensive, but remember the old saying, “You get what you pay for.”

Think of your lines as your boat’s vital signs. When they’re performing well, it’s smooth sailing. But damaged or aging lines are like a weak pulse: they compromise your sail control, making maneuvering your boat akin to paddling with a pool noodle.

Think of your clutches,

blocks, and sheaves as

the highway system for

your cordage. Just like a

real highway, debris and

wear can create

hazardous conditions.

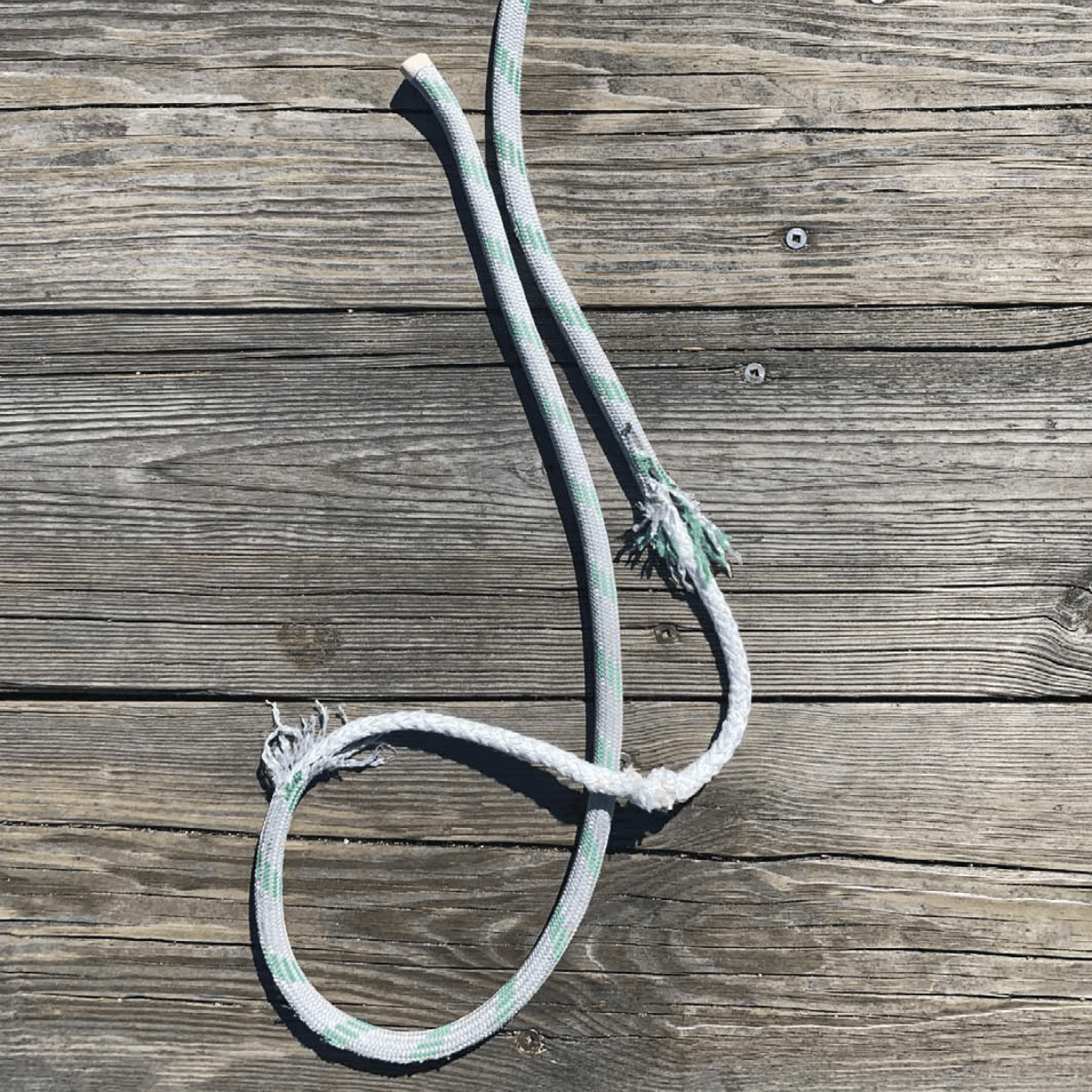

Over the course of a voyage or season, there are numerous things that can occur to damage your lines. Abrasion is one of the usual suspects, and having a line with that “fuzzy” look isn’t a fashion statement, it’s a cry for help.

Abrasion damage shows up as fraying cover fibers, but finding the cause requires some detective work. Follow your line’s path and count each directional change. Those turns? They’re prime suspects for damage.

The top culprits for abrasion are often hiding in plain sight — the mast’s sheave box and exit plates are notorious troublemakers. Inspect them and make sure sheaves turn smoothly and there are no rough edges where lines exit the mast.

Think of sun and salt as the Dynamic Duo. Those perfect sunny days on the water come with a hidden cost. Here’s an interesting fact: Maine sailors replace their lines less frequently than their Florida counterparts. Why? It’s all about location. The closer you sail to the equator, the faster UV damage occurs. Add salt water to the mix, and you’ve got a recipe for accelerated wear.

A word about UV damage: There are two types of damaging UV rays, UVA and UVB. Longer UVA rays are the deep penetrators and damage a rope’s core. UVB rays are shorter and damage the cover of your line. You will see this damage first in the fading of your line. Select polyester lines that have been rated as UV resistant. UV-resistant lines have a polyurethane coating to protect them from the sun. When purchasing cordage, select lines that have been treated. Darker colors retain their color, too.

The obvious remedy for protecting your lines from sun damage is storing them away from the sun or covering them when not in use.

If you sail in salt water, washing lines annually with warm, soapy water removes salt that magnifies sun damage. If you’ve ever seen your lines twist up like a rebellious garden hose, you’ve met a damaging hockle, which can be caused from repeatedly loading and unloading line on a winch. Each twist acts like a knot, which reduces the strength of the line. Got twists? Fix them with a “boat tail.” Tie the line to the stern and let it trail behind while underway. It’s like a spa day for your line.

Remember, your lines are only as good as the hardware they run through. Think of your clutches, blocks, and sheaves as the highway system for your cordage. Just like a real highway, debris and wear can create hazardous conditions. Here’s a pro secret: when it comes to clutches, bigger—line that is—is often better (within specs, of course). A 12-mm line will grip better than an 8-mm line in a clutch rated for 8- to 14-mm rope. It’s like choosing hiking boots—too loose, and you’re asking for trouble.