Recommended line diameters for docking and anchoring lines

The length of the ship is the best criterion for recommending the line diameter for docking and anchoring applications. Based on the ship’s displacement, docking and anchoring lines must be primarily able to withstand the pressure of the flood tide, stream and wind pressure, as a function of the type of the ship. Note: The values provided are for reference only. When furnishing ships with lines, the legislation and registers of the respective countries must be respected in the first place.

| Boat length (feet) | ECO ANCHOR | ECO ROPE | FLEXI DOCK | KEY WEST | LAGUNA | MALAGA | STORMY DOCK | VISION |

|---|---|---|---|---|---|---|---|---|

| 20 ft | 10 mm | 8 mm | 12 mm | 8 mm | ||||

| 26 ft | 12 mm | 10 mm | 14 mm | 10 mm | ||||

| 33 ft | 14 mm | 12 mm | 16 mm | 12 mm | ||||

| 38 ft | 14 mm | 16 mm | 14 mm | 18 mm | 14 mm | |||

| 45 ft | 16 mm | 18 mm | 16 mm | 20 mm | 16 mm | |||

| 52 ft | 18 mm | 18 mm | 24 mm | 18 mm |

Recommended line diameters for sheet lines and halyards from polyester

When using high-strength materials such as Vectran or Dyneema®, the line diameter may be reduced by up to 2 mm. Note: The above stated values are approximate only. The legislation and register of the respective country must be followed when furnishing a boat.

| Boat length (feet) | Sheets* | Halyards* | ||||

|---|---|---|---|---|---|---|

| Main | Spin | Genoa | Main | Spin | Genoa | |

| 20 - 26 ft | 8 mm | 8 mm | 10 mm | 8 mm | 8 mm | 8 mm |

| 27 - 29 ft | 10 mm | 8 mm | 10 mm | 8 mm | 8 mm | 8 mm |

| 30 - 33 ft | 10 mm | 10 mm | 10 mm | 10 mm | 10 mm | 10 mm |

| 34 - 38 ft | 12 mm | 10 mm | 12 mm | 10 mm | 10 mm | 10 mm |

| 39 - 42 ft | 12 mm | 12 mm | 14 mm | 12 mm | 12 mm | 10 mm |

| 43 - 46 ft | 12 mm | 12 mm | 14 mm | 14 mm | 12 mm | 14 mm |

| 47 - 52 ft | 14 mm | 14 mm | 16 mm | 16 mm | 14 mm | 14 mm |

| 53 - 58 ft | 16 mm | 16 mm | 18 mm | 18 mm | 16 mm | 18 mm |

Storage of lines

The maximum storage life of yachting lines in unused condition is up to 5 years.

Optimum storage conditions:

- clean place protected against light,

- without chemical, physical and mechanical impact,

- normal climate (15–25°C),

- relative humidity of about 65 %.

Note:

During the line manufacturing process, the fibres are mechanically doubled, twisted and braided in several stages. Thus the fibres attain a condition of mechanically induced stress. A long-term storage leads to loosening of the material, which means that macromolecules are “relaxing”. This effect is not harmful - quite the contrary: it improves certain properties of the line.

Research showed that the lines that had been optimally stored for several years had better results in tests of dynamic performance than the lines measured immediately after manufacturing.

As for the modern advanced materials, a considerable negative change of the product's properties in a 5-year time interval can be eliminated provided that optimum storage conditions are maintained.

Materials

Our lines and cords are designed to meet the highest standards, the most severe weather conditions, UV radiation and constant abrasion. Instead of natural materials we use synthetic fibers which, compared to natural fibres, have better properties such as greater strength, lower elongation and longer service life.

The following table displays the properties according to the material.

| Material | HMPE | LCP | Aramid fibre | Polyester | Polyamide | Polypropylene multifilament |

| Trade name | Dyneema® | Vectran | Technora | Dacron, Diolen, Travire | Nylon, Perlon | Multitex |

| Tenacity (cN/dtext)* | 28 - 38 | 22 - 25 | 20 - 25 | 7 - 8 | 6.5 - 8.3 | 6 - 7 |

| Elongation at break (%) | 3.5 | 3.3 | 4.6 | 10 - 16 | 16 - 27 | 20 - 23 |

| Specific gravity (g/cm3) | 0.98 | 1.41 | 1.44 | 1.38 | 1.13 | 0.91 |

| Melting point (°C) | 144 - 152 | 330 | carbonization at 500°C | 260 | 220 | 160 |

| Abrasion resistance | very good | good | good | excellent | excellent | good |

| UV resistance | very good | sensitive | sensitive | excellent | good | good with stabilizators |

| Salt resistance | excellent | excellent | sensitive | good | good | good at weak concentration |

| Resistance to acids | excellent | excellent | excellent | predemonantly good | - | excellent |

| Resistance to oil products | excellent | excellent | excellent | excellent | good | good |

| Creep | creep under longterm load | immeasurable | immeasurable | immeasurable | immeasurable | immeasurable |

| Knot strength (%) | 35 - 50 | 30 - 35 | 30 - 40 | 55 - 60 | 60 - 65 | 55 - 65 |

* strength related to fibre fineness. The data provided in the table are for reference only.

For sheet and halyard lines

- we recommend to use materials with low elongation, high strength and long service life

- polyester is used for this category in most cases

- new high-tenacity materials like Dyneema® and Vectran are gaining importance for demanding racing applications

Mooring, anchoring and tow lines

- have to be able to absorb heavy shocks and repeatedly occurring tension, so they have to be elastic and strong

- materials like polypropylene are suitable for use as tow lines (floating materials)

- heavier materials, such as polyamide and polyester, are recommended to be used for mooring and anchoring lines

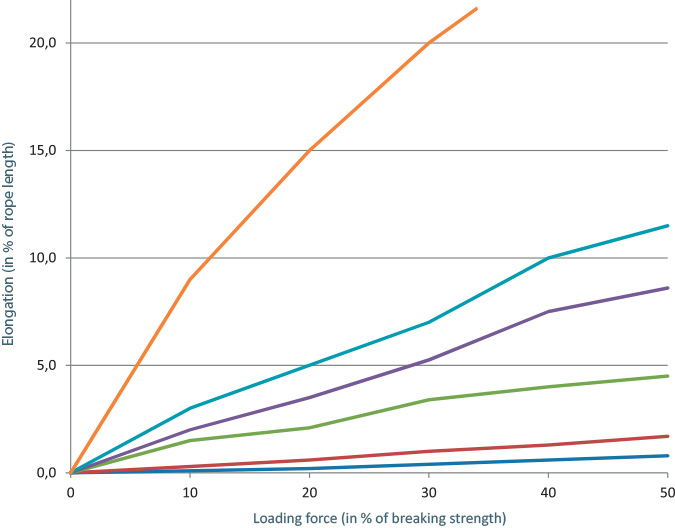

Elongation curves

The term “used“ denotes used regularly under normal weather conditions. These are lab-simulated at tenfold line loading lasting 10 seconds with the loading force amounting to 20% of the maximum strength of the particular line.

- DM 20

- Dyneema®SK 78, Vectran

- Dyneema®SK 78, Vectran with PES Cover Racing Edition

- Double Braided PES with heat set

- Double Braided PES

- Double Braided Nylon